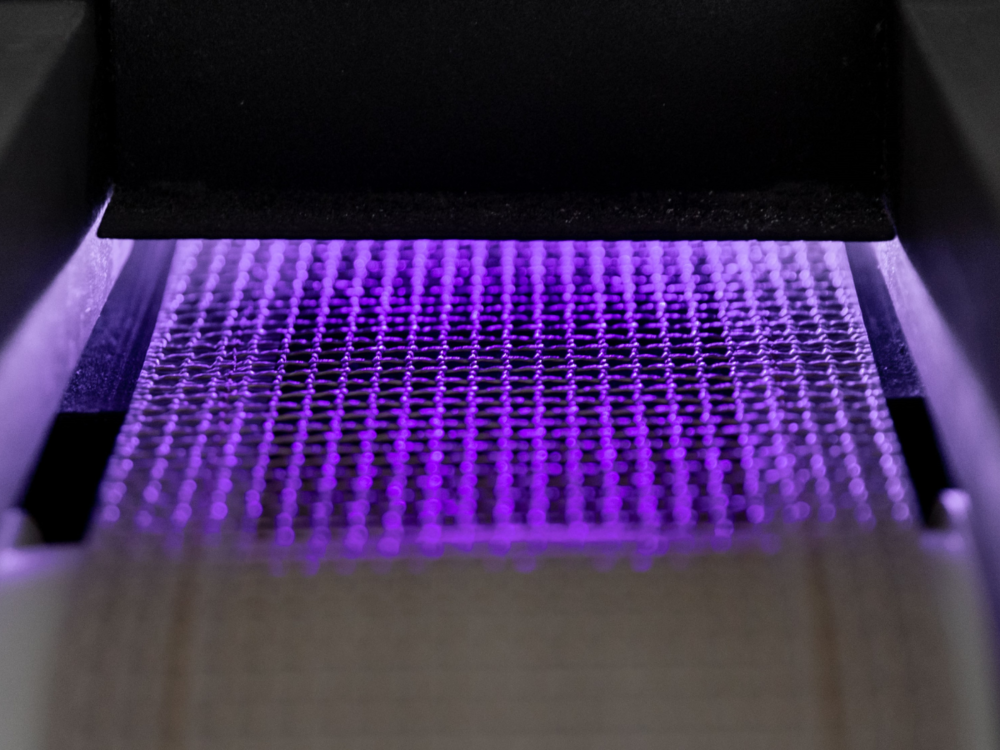

Radiation Curing

P

แสง UV ถูกนำมาใช้ในอุตสาหกรรมในหลากหลายรูปแบบ หนึ่งในนั้นก็คือ curing process โดยอาศัยการกระจายคลื่นของ UV หรือ EB เพื่อให้เกิดปฏิกริยาทางเคมี ในกระบวนการโพลิเมอร์เกือบทั้งหมดต้องอาศัย UV และ EB ในการ Curing แทบทั้งสิ้น

Radiation curing is a process where material is exposed to either UV energy or Electron Beam (EB) energy. There are two primary uses for radiation curing. One is for cross linking. This process uses primarily EB technology. A good example of the use of this technology is for the manufacturing of stretch wrap film. The second application is for a polymerization process. Monomers and oligomers when exposed to radiation combine to form a solid. If UV radiation is used a photo initiator must be present to start the polymerization process. A good example of this would be for the curing of ink on labels for soap bottles.

Oxygen inhabits the reaction of radiation cured chemistries. In some case the Oxygen inhabitation is not important and thus the process can happen in air. Most chemical suppliers try to supply chemistries that will react in air.

However whenever EB technology is used the curing chambers must be inerted with N2 because there are no photo initiators present to start the reaction. Because of this oxygen analyzers are typically an integral part of each EB system when it is sold. When inerting most EB applications would like to see levels of O2 below 100ppm. EB has been used in a number of applications. Some of these are: shrink wrap, silicone release linings, magnetic tape media, abrasive materials, and many wood and ceiling tile applications.

UV chemistries usually require nitrogen inerting when specific characteristics are required. As an example: plastic overlays require certain gloss to be easy to read and look nice. The gloss can be changed by the level of N2 in the curing chamber. Another application is for printing companies that print signs for outdoor use. Many of the chemistries used in this process require Nitrogen inerting to give the inks long term stability and fade resistance. During the manufacture of tapes-one side of the material has to have a silicone release agent applied or the tape would just stick together. Many of these coating facilities use UV cured silicone release materials. GE manufactures a material that can be used on plastic. This material does not need to be cured in an inerted environment. Goldschmidt manufactures a material that has different release characteristics and can be used on both paper and plastic materials. This chemistry requires a nitrogen inerted environment. Most UV applications that require nitrogen inerting are confidential. Almost all UV companies try to design the chemistry to be an air cure chemistry.

All EB systems are able to be nitrogen inerted. Only UV systems that are designed to be nitrogen inerted can be nitrogen inerted. Customers will pay a 50% premium for a system that can be nitrogen inerted. Most UV companies will offer oxygen analyzers as an option to purchase, but leave the final decision up to the end user. จะเห็นได้ว่าในหลายๆ งานผลิตสินค้าที่ยกมาเป็นตัวอย่างนั้น คือการใช้ UV และ EB ใน สภาวะ Inert แทบทั้งสิ้น ซึ่งลักษณะเฉพาะของงานนี้ก็คืออุปกรณ์วัดออกซิเจนนั้นจะต้องทำงานตั้งแต่ระดับ ppm ไปจนถึงเปอร์เซ็นต์ ซึ่ง Tasatec มีเคล็ดลับ เซ็นเซอร์ ให้ทำงานตอบสนองช่วงการวัดทั้งหมดได้