เครื่องทดสอบอเนกประสงค์หรือ UTM เป็นเครื่องทดสอบคู่ที่สามารถทำการทดสอบแรงอัดและแรงดึงได้

The Universal Testing Machine or the UTM is dual-testing machine can perform compression and tensile testing.

The Universal testing machine enables measurement of firmness and harness. It is based on a physical property called the indentation force deflection (IFD). Which is calculated by determining the force required to deflect a test piece. Which is a percentage of its original thickness using a circular indentor. This applies a force, while also recording the degree of indentation.

Additional information

Description

Compression and Tensile Testing

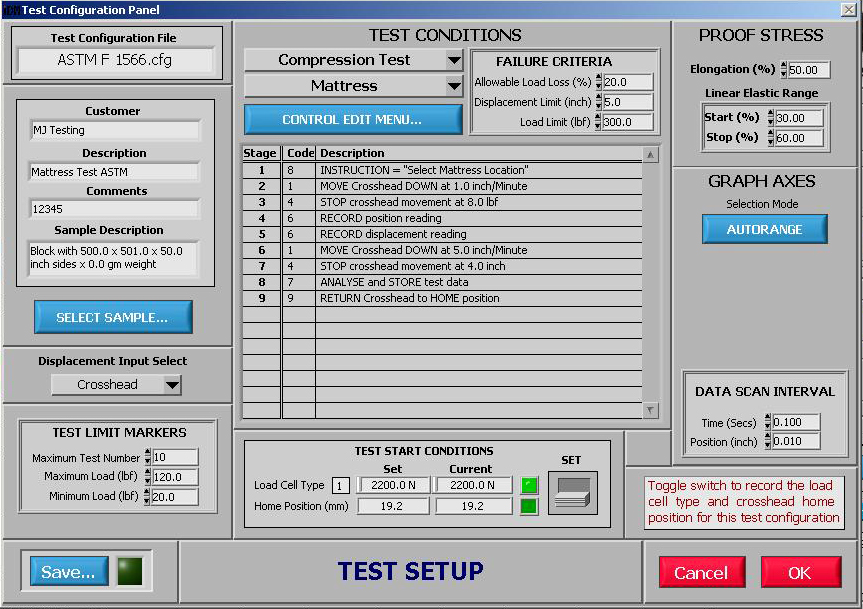

IDM Instruments’ UTM comes with fixed dual testing capabilities. Which comprises of compression testing on the inner frame. As well as tensile strength testing on the outer frame. This incorporation of dual testing space design is beneficial. as it eliminates the need of having two machines required for testing. The same machine is useful for both tests. The twin column bench-mounted UTM has a strong and durable frame. Thus, can withstand many years of use. It offers excellent accuracy and ease of use. It operates on the IDM Instruments Pty Ltd software program.

What is the importance of the compression test?

Why choose IDM’s Universal testing Machine for tensile and compression testing?

Custom Universal Testing Machine

We also manufacture custom UTM to accommodate as per customer needs. For example, a wider testing space removes the sample length restrictions. This includes cutom load cell capacities that can be expanded or reduced in tonnage based on the test and material being tested.

Why is tensile testing important?

Tensile testing is a common method used to test quality of materials. The tensile of a sample is determined by the force required to elongate (applying tension) until it reaches breakage point. For example, a rope is pulled from both ends until it reaches the breaking point. This test helps quality experst determine whether the material/ product would sustain different circumsances it goes through. The minimum tensile strength is determined by the testing standard referred. The applications of tensile testing are limitless. From textile companies to research orgnisations to aerospace companies, tensile tetsing is performed by every quality testing department.

We have so mnay clinets who have used our universal testing machine to test tensile of foam, ropes, wires, plastic, textiles, etc.

How to use our universal testing machine?

Applications

- Polyurethane

- Plastic

- Rubber

- Textiles

- Springs and many other materials

Benefits

- Easy to use

- Fast results

- Accurate

Standards

- ASTM D3574 – Test B – Standard Test Method for Testing Flexible Cellular Materials Measurement of Indentation Force Deflection Using a 25-mm [1-in.] Deflection Technique

- ASTM D3574 – Test C – Compression Force Deflection (CFD) of Flexible Polyurethane

- ASTM D3574 – Test E – Tensile Testing of Flexible Polyurethane Foam

- ASTM D3574 – Test F – Foam Tear Testing

- AS 2281 – Flexible cellular polyurethane for seat cushioning and bedding

- AS 2282.8 – Methods for testing flexible cellular polyurethane Determination of force deflection

- ASTM F1566 – Standard Test Methods for Evaluation of Innersprings, Box springs, Mattresses or Mattress Sets

- ISO 3386 – Polymeric materials, cellular flexible — Determination of stress-strain characteristics in compression — Part 1: Low-density materials

- ISO 2439 – Flexible cellular polymeric materials — Determination of hardness (indentation technique)

- ISO 1798 – Flexible cellular polymeric materials — Determination of tensile strength and elongation at break

- ISO 8067 – Flexible cellular polymeric materials — Determination of tear strength

- GB 10807 – Polymeric materials cellular flexible–Determination of hardness (indentation technique)

- JIS K 6400 – Test Methods for Flexible Polyurethane Foam

Features

- Loading System – closed loop micro computer, which drives a ball screw and nut for its vertical movement

- Maximum Capacity: 0-2224N (custom available)

- Travel (mm) approx.: 600mm x 0.1mm with out tensile jaws

- Speed (mm/min) 1 to 500 mm/min

- Return Speed (mm/min) 500mm/min

- Speed Accuracy better than +0.5%

- Tensile Load Measurement Accuracy – 0.5% of indicated value or ±0.5% of full scale

- Load auto-zeroing, load cell discrimination

- Safety function for overloading provided

- Max. Stroke Limiter upper/lower – 2 points

- 2 load cells, 250 Kg for compression and 50kg for tension

- Foam compression platens area: 400mm x 400mm (standard)

- Test area of 600mm wide and not restricted at front and rear

- PC controlled

- Electrical: 220/240 VAC @ 50 HZ or 110 VAC @ 60 HZ

- Dimensions: 1,215 mm x 975 mm x 515 mm

- Weight: 85 kg SOFTWARE FEATURES:

- Data Sampling is adjustable from 1-200,000Hz

- Position or Load control

- Test parameters displayed with graph simultaneously

- Real time graphic display of data

- Overlay display of data curve possible during test

- Selectable graphical display presentation

- Test Methods programmable

- Data can be sent to Excel

- Other test methods can be programmed by the operator

- Out of range alarm and stop

- Cyclic testing with data recording during cycle

- Auto return after a test is selected

- Calibration File to calibrate the instrument

- Statistical analysis requirements

- Printable Reports

- Windows based software OPTIONS:

- Load Cells

- Grips

- Compression Platens

- Custom made frame to suit wider samples

No Accessories data.

No Media Data.

หากลูกค้าสนใจสินค้าหมวดหมู่

เครื่องทดสอบอเนกประสงค์ Universal Testing Machine

สามารถติดต่อเราได้ที่นี่