SpecMetrix offers exclusive in-line coating thickness measurement systems for coating and production lines. Designed to provide non-contact, non-destructive and real-time thickness measurements for applied coatings.

SpecMetrix สำหรับการวัดสารเคลือบในสายการผลิต เป็นโซลูชันขั้นสูงที่ออกแบบมาเพื่อวัดความหนาของสารเคลือบแบบเรียลไทม์อย่างแม่นยำและไม่ทำลายวัสดุโดยตรงในสายการผลิต ระบบนี้ช่วยเพิ่มประสิทธิภาพการดำเนินงาน ลดของเสีย และรับประกันคุณภาพที่สม่ำเสมอในกระบวนการเคลือบ

Additional information

Description

Brought to you by SpecMetrix, dedicated to delivering more precise coating thickness measurement data to industrial manufacturers.

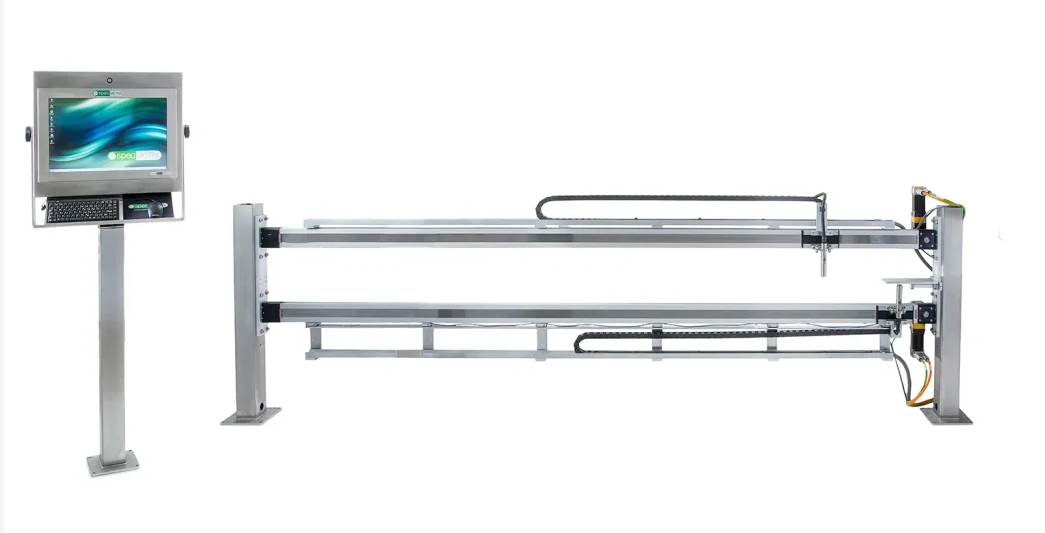

We are proud to offer In-line Coating Measurement Systems that can be easily integrated to your production lines for immediate quality control and process control benefit. All systems use our innovative, patented ROI technologies that provide you with non-contact, non-destructive and real-time thickness measurement data during the coating process over a diverse range of substrates.

Streamline QA processes – in real time

Designed to work alongside your production lines, we have In-line Coating Measurement System configurations to meet your site’s requirements and provide you with precise and insightful coating thickness data. All coating measurements are captured in real-time and are displayed on the intuitive SpecMetrix touch screen interface, allowing operators and process teams to immediately improve coating process control and make quality adjustments.

Features & Benefits

Versatile measurements

SpecMetrix® In-line Coating Measurement Systems are extremely versatile. No matter the substrate you are coating, we will likely have an in-line catering and layer thickness measurement solution to meet your wet or dry coating process control and quality assurance needs.

In-line systems for coated coils:

- Precise coating thickness measurements of coated, treated or laminated coils

- Measures wet or dry coatings down to submicron levels

- Clear, colored or pigmented coating thickness measurements

- Coatings over any metal substrate, including aluminum, steel, tinplate, cold-rolled, Galvalume; and even coatings over any paint color

- Real-time measurements of applied pretreatments, primers, base coats, top coats, lacquers, back coats, laminates, clear coats and other coil coatings

In-line systems for coated flexible packaging materials and roll-to-roll (R2R) processing:

- Precise coating and layer thickness measurements on production rolls, laminations and converted products

- Measures wet or dry applied coatings and layers

- Real-time measurement of clear, colored or printed coatings

- Coatings over any flexible substrate, including foils, primed paper, plastic and films

- Real-time measurements of applied film and web coatings including adhesives, barrier, scratch resistant, wet silicones and other performance coatings

Specifications

SKU:

Applications: Coating Testing

Materials: Inks and Coatings

Measurement range for coated coils: 0.7 to 350 microns* (clear/transparent coatings), 0.7 to 75 microns* (pigmented/non-transparent coatings). *Dependent on selected optical packages

Measurement range for coated flexible packaging materials and R2R processing: 0.3 to 250 microns (coating thickness)

Accuracy: +/-3% of coating thickness (nominal) *based on accuracy verification using NIST traceable thickness standards over the entire measurement range of 0.2 to 250 microns

Web Speed: Up to 2000 feet/minute, Up to 600 meters/minute

Measurement Speed: Up to 150 per second

Scanning Speed: Up to 5″ (125 mm)/second

Temperature Range: 0 to 55 °C

Web Width: Available in standard industrial lengths, and customizable at additional cost

Output metrics for coated coils systems: microns, mils, g/m2

Output metrics for coated flexible packaging materials and R2R processing: microns, mils, mg /in2, mg/4in2, g/m2, mg /cm2, lbs/ream

Operating System: Windows® platform

Manufactured: Made in USA

Certifications: CE approved, UL approved and CSA approved

No Accessories data.

หากลูกค้าสนใจสินค้าหมวดหมู่

SpecMetrix® In-line Coating Measurement Systems – การวัดสารเคลือบในสายการผลิต

สามารถติดต่อเราได้ที่นี่