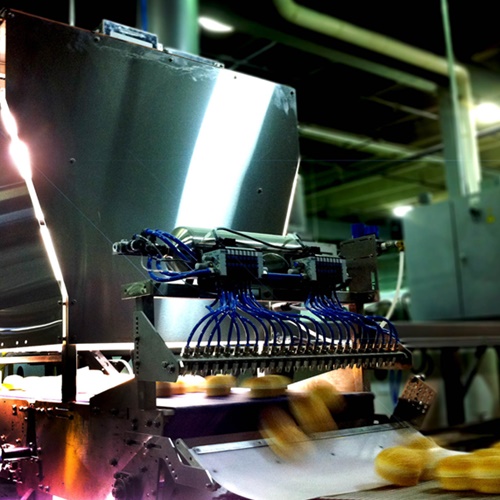

ระบบตรวจสอบคุณภาพอาหารแบบ inline ที่ เป็นการทำงานร่วมกันของ High Speed Camera, Laser Beam, และ Imagine Software คอยตรวจสอบขนาด รูปทรง และสี ที่ผิดเพี้ยนไปจากที่กำหนดไว้ พร้อมระบบ ejection

Inline Vision Inspection for Food Manufacturers

Real-Time Analysis, Inspection, & Statistical Control. In-Line vision inspection systems use a selection of high-speed cameras, a laser, and imaging software to detect and measure objects as they move along the included conveyor belt.

Additional information

| Measure Component | color, shape, size |

|---|

Description

เครื่องวัดคุณภาพของอาหาร เช่น รูปร่าง ขนาด และสีของขนมอบ เนื้อสัตว์ สัตว์ปีก ชีส ไข่ ผลไม้ ผัก และอาหารสัตว์เลี้ยงเพื่อตรวจหาปัญหาด้านคุณภาพ โดยใช้ระบบตรวจสอบด้วยภาพในสายการผลิตใช้กล้องความเร็วสูง เลเซอร์ และซอฟต์แวร์เกี่ยวกับภาพที่ได้รับการคัดสรรเพื่อตรวจจับและวัดวัตถุขณะเคลื่อนที่ไปตามสายพานลำเลียง

Inline Vision Inspection for Food Manufacturers

Our customizable In-Line Vision Inspection Solutions (EyePro or Sightline) are designed to be quickly installed into any new or existing production line. These turn-key solutions offer 3D, full color, 360-degree product quality inspection solutions capable of extracting multiple quality parameters simultaneously at speeds of up to 100 objects per second. For advanced process control, each system is equipped with a conveyor, cameras selected for your specific application, a choice of rejection options, and our proprietary measura® software suite.

Benefits

- Know more about your product compared to manual methods

- Make quick decisions and adjustments to the production line using the analysis data

- Ensure that only products meeting your specifications reach the customer

- Ensure consistent product quality between batches, shifts, and sites

- Save costs and reduce waste, which improves your company’s bottom line

- Brand protection

- Save time with reporting, all results are saved & organized

- Achieve competitive advantages

Applications

Measure Quality Where It Matters

Typical Applications Include:

- Measurement of physical product attributes such as shape, size and color of baked goods, meat, poultry, cheese, eggs, fruit, vegetables and pet food to detect quality issues

- Identification and rejection of non-conforming products from the production flow

- Detection of foreign objects

- Generate production metrics (item counts, uptime, throughput, etc.)

Finished Product Examples:

- Bread Products (loaves, baguettes, buns, bagels, english muffins, croissants, muffins, etc)

- Cookies, crackers, biscuits

- Frozen pizza and pizza bases

- Snack Foods (snack bars, pretzels, potato chips, French fries, desserts, chocolates, candies, chewing gum, etc)

- Cheese Products (blocks, snack pieces, wax covered, etc)

- Meat and Poultry (Raw, breaded, grilled, patties, etc)

Features

- Integrates seamlessly into existing production lines

- 100% inspection with rejection, up to 100 objects/second

- Variable speed inspection conveyor included

- Operator Interface included for full control at the line

- Various rejection mechanism choices

- Supports multiple camera and lighting types

- Optional bottom and side cameras

- Built-in library with 100+ measurements and growing

- Generates production metrics (uptime, throughput, etc.)

- Customization available upon request

- Models available: IL-300 to IL-2000, Q-Bake

No Accessories data.

No Media Data.

Additional information

| Measure Component | color, shape, size |

|---|

หากลูกค้าสนใจสินค้าหมวดหมู่

ระบบตรวจสอบคุณภาพอาหาร Inline Vision Inspection for Food Manufacturers

สามารถติดต่อเราได้ที่นี่