เครื่องผสมสารประกอบโฟมความเร็วสูง เพื่อผลิตตัวอย่างที่ผสมอย่างดี เพื่อสร้างตัวอย่างเพื่อการทดสอบและการควบคุมคุณภาพ

The High Speed Mixer is useful rapid mixing of foam compounds to produce a well-mixed sample pat. This is to form a sample for testing purposes as well as quality control. It is made from Stainless Steel. Thus, it assists easy cleaning and avoids corrosion. Featuring automated mixing as well as variable mixing speeds for added ease of use.

Additional information

Description

The mixer has three mixing times and three different testing speeds. Thus, it enables 9 combinations. Any of these combinations create a sample pat which is entered onto the PLC once values are set on the PLC. A hand controller initiates the test enabling the production of sample pat. This is according to set curing times.

High Speed Mixer Apparatus

The High Speed Mixer is made from Stainless Steel for corrosion protection and for ease of cleaning. The mixing shaft is driven by servo motor to maintain constant torque, and to produce high RPM. The High Speed Mixer has been programmed to reach 2000 RPM; however, this can reach 2400 RPM if programmed.

Pneumatic cylinders are used to clamp the cup in position for mixing. A two hand control pendant is used to operate the machine, and digital timers are used to measure product curing times.

A PLC controller is used to set the speeds and run times.

Optional Items

Procedure

• Turn ON the Power isolator switch (located on the right hand side of the electrical cabinet).

• Wait 20 seconds for the drives to initiate. When Step 1 is displayed on the top left corner of the PLC display, then the machine is ready to operate.

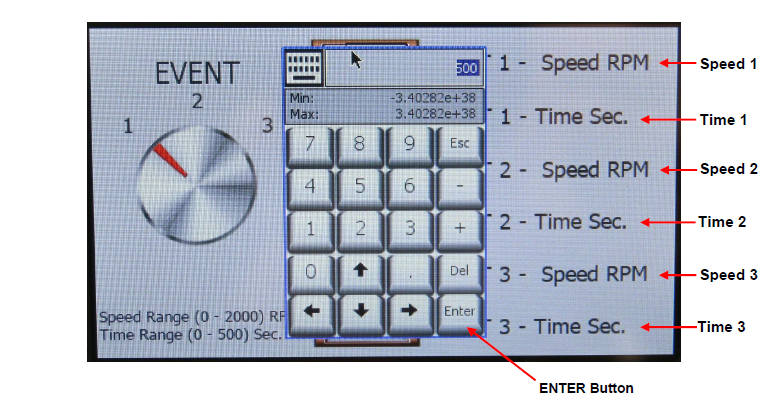

• Set the RPMs and mixing times for each Event on the PLC controller. The labels indicate:

- S1: Speed 1

- S2: Speed 2

- S3: Speed 3

- T1: Time 1

- T2: Time 2

- T3: Time 3

Press the appropriate area on the touch screen to adjust the variable speed or time. Enter in the required value using the numbered keypad. Press the Enter button to store the values.

• Weigh and pour chemicals into the cup for the first mixing event.

• Place the chemical cup securely into the clamp plate. Ensure that it is all the way back into the U-shape groove

• Simultaneously press both operating buttons on the two-hand control pendant, and hold until the cup has fully retracted against the upper sealing face. This will initiate the first mixing event. The cup will be confirmed to be in position by two plunger switches pressing against the cup flange. If the cup is not in place, then the process will not continue.

• The mixer will operate for the set time and RPM, then the clamping cylinders will retract and the cup may be removed.

• Add the next chemical(s) for the process

• Simultaneously press both operating buttons on the two-hand control pendant, and hold until the cup has fully retracted against the upper sealing face. The second mixing event will occur for the set time and RPM. When the cylinders retract to lower the cup, the 3 timers on the control cabinet will start.

• The operator will then observe the finished product, and stop each timer as required curing points are achieved. This is done by pressing the white buttons (T1, T2, T3) on the top of the two-hand control pendant.

Applications

- Foam

Benefits

- Easy to use

- Fast results

- Accurate

Features

- Timed mixing sequence

- Variable mixing speeds

- Automated mixing

- Mixing Speeds: up to 3000rpm

- Stainless Steel construction

- Air Supply: 80 psi / 600 kPa

- Electrical: 320/440 VAC @ 50/60 HZ / 3 PE

- Dimensions: 860 mm x 560 mm x 350 mm

- Weight: 120 kg OPTIONS: Options:

- Mixing Blades

- Bench mounted or floor standing unit

No Accessories data.

No Media Data.

หากลูกค้าสนใจสินค้าหมวดหมู่

เครื่องผสมสารประกอบโฟมความเร็วสูง High Speed Mixer

สามารถติดต่อเราได้ที่นี่