APPLICATION NOTE LD12-6

LD12-6 Increasing argon production with the MultiDetek วิธีการเพิ่มปริมาณการผลิตแก๊สอาร์กอนโดยการวัดระดับไนโตรเจน MultiDetek

วิธีการง่ายๆที่เราจะเพิ่ม ปริมาณการผลิตแก๊สอาร์กอน โดยไม่ต้องลงทุนอะไรเพิ่ม ก็คือการวัดระดับไนโตรเจน ที่ Low Pressure Column ของหอกลั่น ให้ปริมาณไนโตรเจนที่อยู่ในเนื้ออาร์กอน อยู่ในระดับที่เหมาะสม ยอมรับได้

บทความนี้อธิบายวิธีการง่ายๆถึงการวัด ไนโตรเจนที่เจือปนอยู่ ด้วยเทคโนโลยี Plasma มาดูกันค่ะ

Air is composed of nitrogen (78.09%), oxygen (20.94%) and argon (0.934%). To produce pure argon, distillation process separates the air constituent by the use of distillation columns. Such installation on an air separation plant is used for many years.

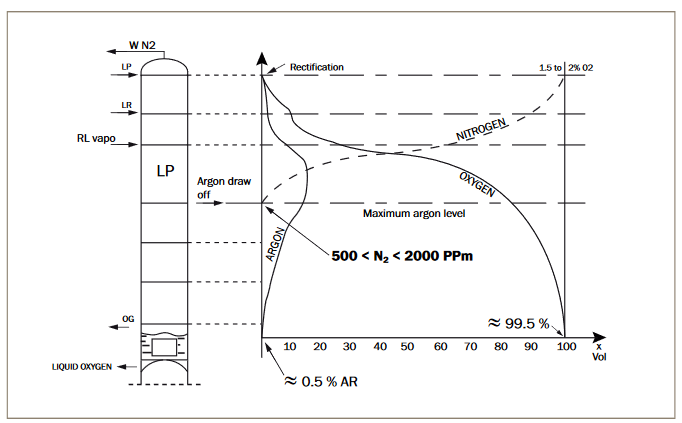

This separation process is based on vapor pressure of each component. Argon is taken from a low pressure column and introduced in a second column called crude argon. Since argon vapor pressure is close to oxygen, and also between nitrogen and oxygen, its extraction is between those two other components in the low pressure column before being introduced in the second column.

However, the level of nitrogen can be problematic when introducing the extracted gas to the crude argon column. Introducing high volume of nitrogen in the crude argon column will make it stop working. Dumping phenomenon can also arise from the crude argon column.

The extraction of argon in the low pressure column is critical, the goal is to get as much as possible argon and reduce the nitrogen level.

Figure 1 shows the vapor pressure of each compound in such column. The maximum level of argon has too much nitrogen. A compromise between argon and nitrogen level must be done.

Most of the plants will then take argon at a point where it is safe to keep nitrogen level low. Nitrogen is lower, but argon as well. Oxygen is then relatively high in the crude argon column. Typical analytical tools are the oxygen and argon measurement. Nitrogen can be approximated and you keep the introduction of nitrogen at minimal level. Such analysis method gives a safe system, but not optimal argon production can be achieved.

WHAT CAN BE DONE?

By using proper analytical tool to measure nitrogen level in the low pressure column, the plant can reach the maximum level of argon extraction with the acceptable nitrogen in the crude argon column. The LDetek’s MultiDetek is the ideal tool to measure nitrogen in oxygen/argon mixture. By measuring continuously nitrogen in such mixture, optimal argon production can be achieved. In some cases, increase of 5% argon can be achieved just by measuring nitrogen level accurately.

The MultiDetek can be interfaced with any acquisition system on ASU. Analog signal or digital signal can be provided. Ethernet connection is also available.Such analyzer is easy to operate with its user friendly interface and can operate 24/24 to ensure extraction is well tuned up. Such MultiDetek is using the PlasmaDetek technology with nitrogen selectivity. This avoids any oxygen trap consumable.

CONCLUSION

The pay back of such analytical tool is fast. It will operate for many years and gives optimal efficiency of any argon production plant. The combination of MultiDetek platform with the PlasmaDetek technology is a reliable, efficient and accurate system that any plant is looking for.