Moisture in Wood Pellets

เชื้อเพลิงไม้อัดแท่ง เชื้อเพลิงชีวมวลอัดเม็ด เชื้อเพลิงไม้อัดเม็ด หรือเศษไม้อัดเม็ด เป็นเชื้อเพลิงประเภทหนึ่งที่ผลิตจากขี้เลื่อยหรือเศษไม้ที่นำมาบดให้เป็นผงละเอียด ก่อนนำไปอบแห้ง เพื่อลดค่าความชื้น

การควบคุมความชื้นเศษไม้อัดเม็ดเหล่านี้ ควรใช้เซ็นเซอร์ออนไลน์ที่วัดความชื้นอย่างต่อเนื่องตลอดกระบวนการผลิต โดยเครื่อง Process Sensors จะช่วยให้ผลิตเชื้อเพลิงไม้อัดแท่ง เชื้อเพลิงชีวมวลอัดเม็ด เชื้อเพลิงไม้อัดเม็ด หรือเศษไม้อัดเม็ดเหล่านี้ให้มีคุณภาพสูง ด้วยการวัดความชื้นที่ล้ำสมัยด้วยเทคโนโลยี NIR

Application Briefs – Wood Products

Moisture control is one of the major challenges for pellet plant operators. PSC offers a solution with an online sensor that provides continuous moisture measurement throughout the process. Being proactive with moisture measurement offers cost savings in the manufacturing process and eliminates the chance of packaging wet or low-quality product. It is Process Sensors’s goal to help the mill make a high-quality pellet by providing state-of-the-art moisture measurement with NIR technology.

Waste sawdust and wood chips are delivered to the pellet plant by truck or rail car then stacked outside in large mounds. A front loader is used to take the sawdust from the different piles and load the feed system for the plant. Wet and dry sawdust is selected by the tractor operator in an attempt to keep a moisture balanced load heading into the dryer system. This green wood generally has a moisture content of 20 to 50%. If the sawdust is stored outside the moisture can be higher or lower depending on the weather. It can be a challenge for the loader operator to keep an even mix of wet and dry sawdust going into the feeder system.

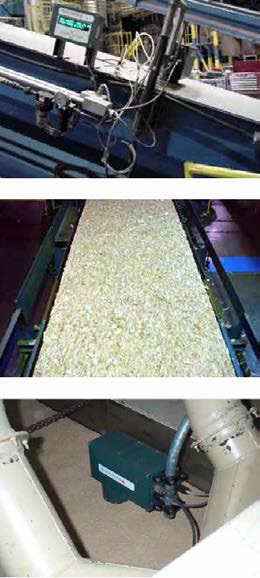

A Process Sensors Corp. moisture meter is very helpful to the loader operator as a sensor is mounted on the screen infeed conveyor and a large display is mounted outside for the operator’s use.

The first step in the process is to screen the sawdust and wood chip mixture to separate the fine chips from the coarse chips. The coarse chips are ground to reduce their size for quick and even drying. They are then remixed for temporary storage.

After a second screening to separate the fines from the coarse, the coarse chips are reduced in size with the hammer mill. The hammer mill output and fines are again mixed and stored in bins by moisture content.

The sawdust is then conveyed into a large drum dryer where the moisture is reduced to less than 10%. The sawdust is then conveyed into a cyclone dryer where high speed swirling air removes additional water vapors and cools the product down.

A PSC moisture meter is typically mounted on the dryer outfeed to ensure the moisture is approximately 10%. If the moisture is higher than 10% the sawdust will be directed to a moist bin. Typically, moist bins and dry bins will be blended for the ideal moisture level going into the pellet press. Use of PSC moisture meters on each of the bin outputs can offer additional information to aid in the blending process.

One of the most important measurements is of the final mixture after blending and prior to the press. A PSC moisture meter is used to continuously measure this moisture level going into the pellet mills. The analog output signals from the sensor can be used to forward feed a PLC. The PLC can be programmed to take control of the power level and speed of the press thus creating a more consistent product. This mixture is now ready to be pressed into pellets or sent back to the dryer as fuel for the burner.

The processed sawdust is conveyed into the pellet press where the pellets are formed under very high pressure. This high pressure drives off additional water and causes the natural wood lignites to bind the sawdust into shiny hard pellets. After the pressing, the finished pellets go through one final screening to recover any leftover sawdust for recycling. The cooled and screened pellets are stored in silos while waiting to be bagged and shipped. The standard package is a 40 lb. moisture protected bag for household heating. A major market is Europe, where many homes and power plants use wood pellets as their energy source.